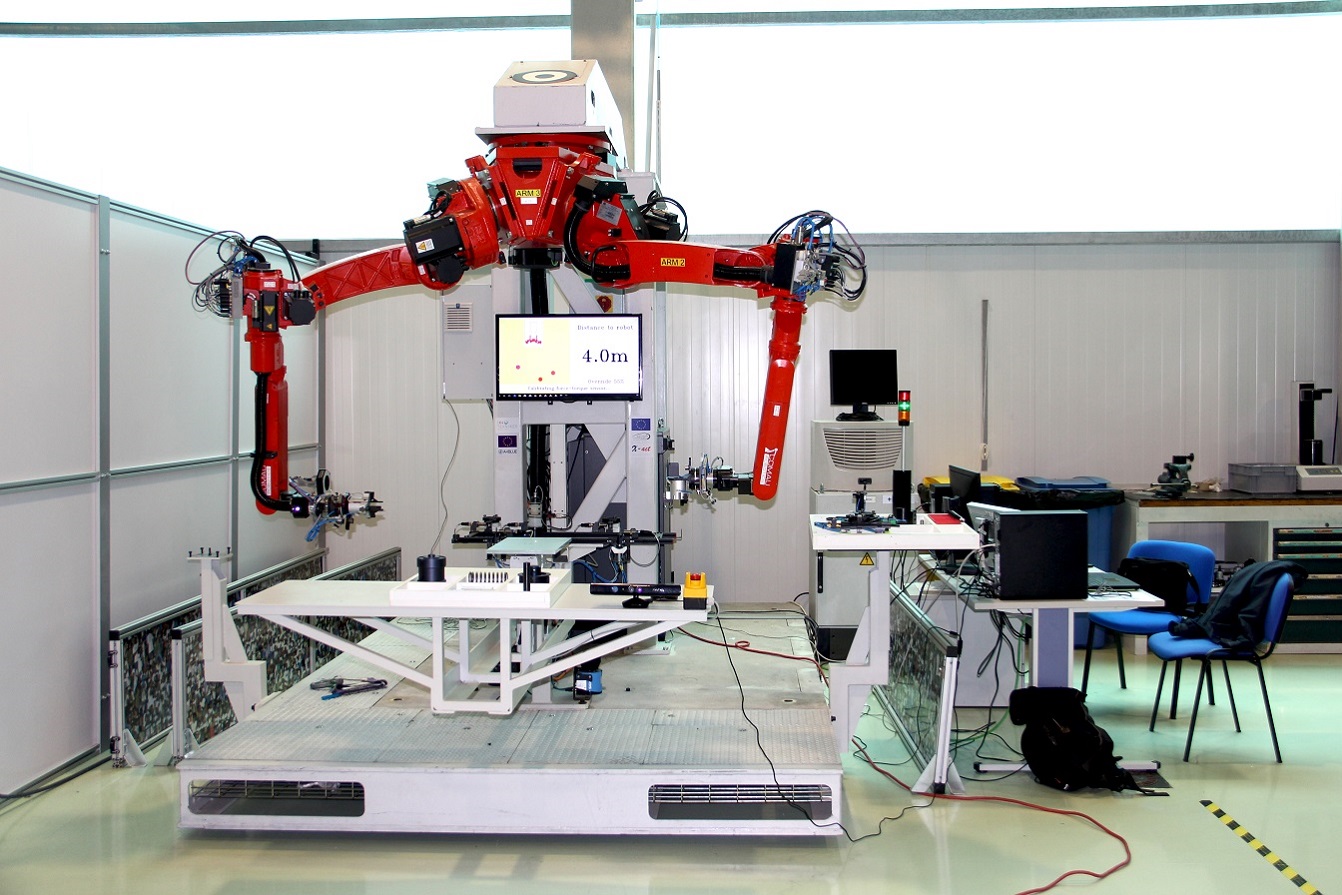

Demonstrator 1 IK4-TEKNIKER

The developed technologies enable robust wireless communication between the mobile robot and the dual-arm workcell to extend robotic workcell capabilities. The dual-arm robot interacts both with a human worker during the assembly operation and a mobile robot that is performing logistics-related operations.

Demonstrator 2 SmartFactory-KL

In the neutral test factory, new cognitive technologies were developed and prototypically tested at SmartFactory-KL. First and foremost, access to production information was improved by the introduction of an Active Digital Product Memory. SmartFactory-KL has also introduced an algorithm that dynamically reschedule the production sequence when ordering or cancelling products. In addition, artificial intelligence techniques were used to take over flexible quality monitoring in the plant. This was introduced in the form of visual quality control, which can dynamically record the condition of a product and forward this information.

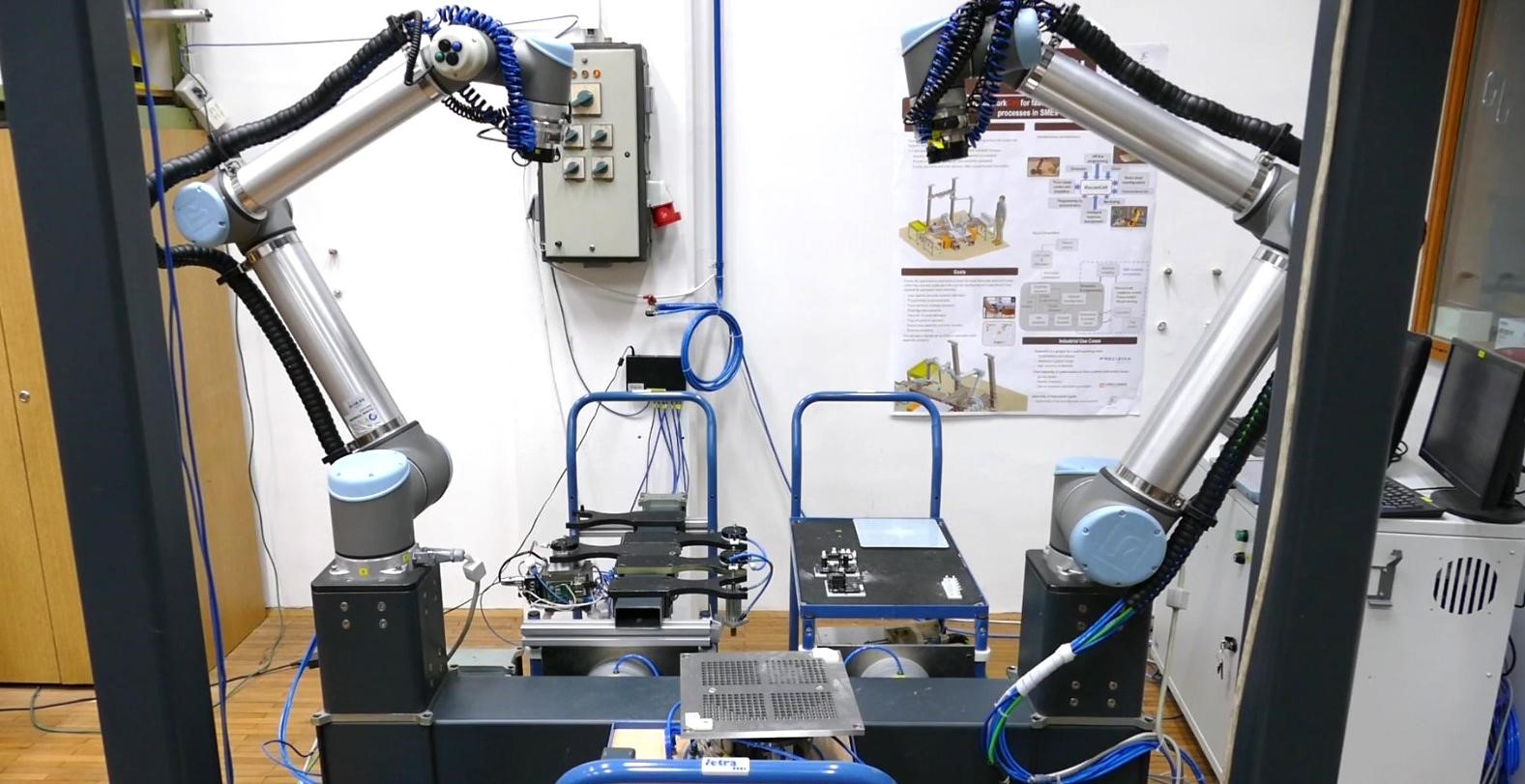

Demonstrator 3 JOZEF STEFAN INSTITUTE

The reconfigurable workcell developed at JSI is based on novel ICT technologies for programming, monitoring, and executing robot assembly operations autonomously. The workcell supports the integration of state-of-the-art digital technologies including advanced robot programming by demonstration, gripper finger design using 3D printing and supported by a finger exchange system, integration of deep neural networks for visual quality control, and the integration of cloud-based services and edge computing.

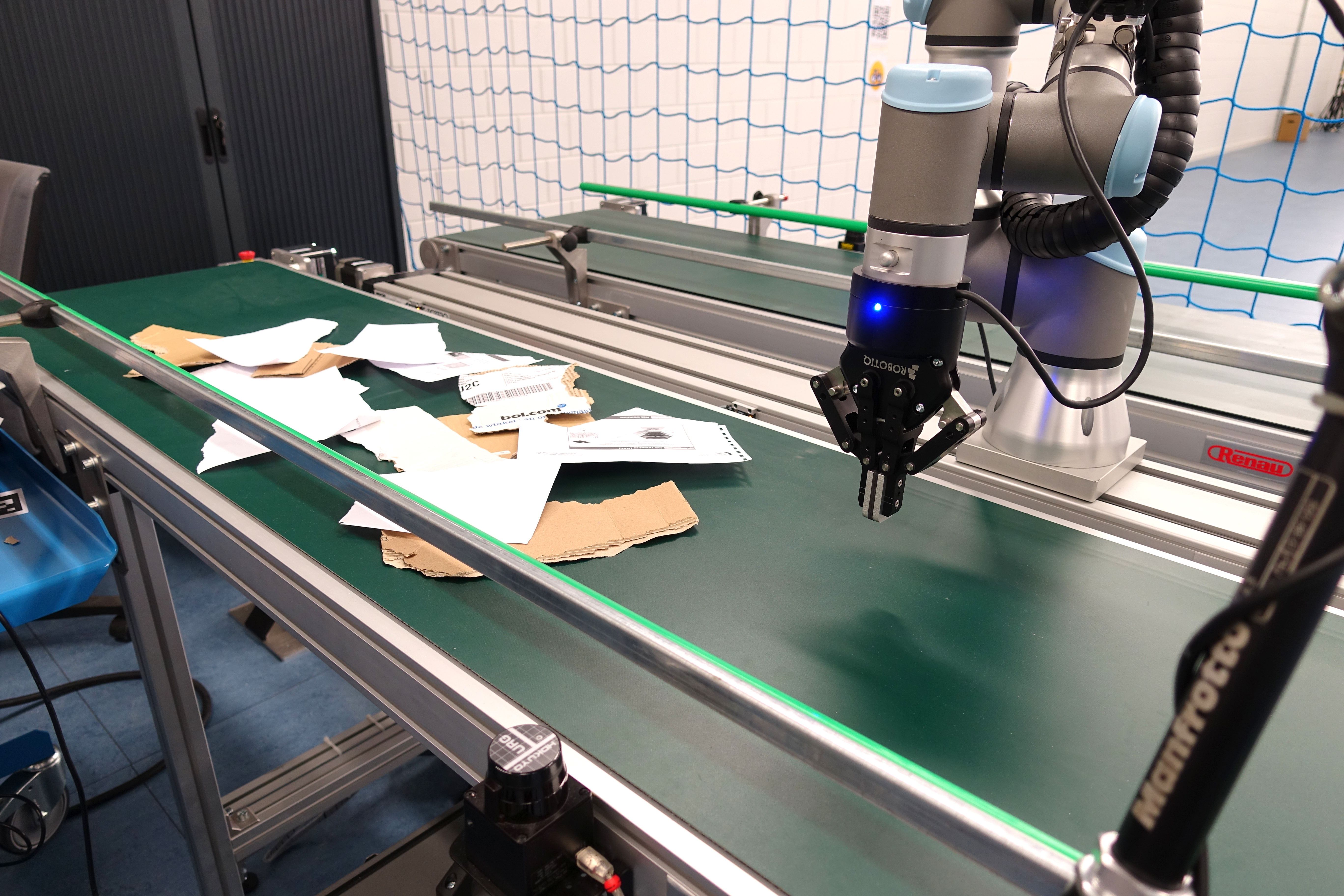

USE CASE 1 STORA ENSO

A big challenge in paper recycling is the separation of cardboard and waste materials from paper. Within the AUTOWARE project, a detection framework which can swiftly change between the materials was created. This novel technology offers the possibility to use vision-based algorithms based on combinations of complex features such as shape, form, colour and can be reconfigured to recognize new products.

Use Case 2 SMC

The use case 3 deals with the support of the manual assembly process of SMC pneumatic cylinders by applying human-robot collaboration. By implementing the AUTOWARE technology, some of these manual process steps were automated to increase effectiveness and productivity and to relieve the employee from monotonous and repetitive tasks.